Cyclotron Spare Parts

Cyclotron Equipment

All our products and spare parts are built for specific customer requirements and are easily adaptable to various accelerators and conditions. We have developed standard designs for the commonly used GE PETtrace 800 Cyclotron, GE Minitrace Cyclotron, IBA Cyclone 18/9 Cyclotron, and Siemens RDS 111 & HP ECLIPSE but other designs can be made if required. Please inquire if you have specific spare parts needs. The designs represented below are produced for our customers. The possibilities are unlimited.

Target body Spare Part List;

Ready For Production And Shipment of Original Cyclotron Spare Parts;

Siemens RDS 111 Cyclotron;

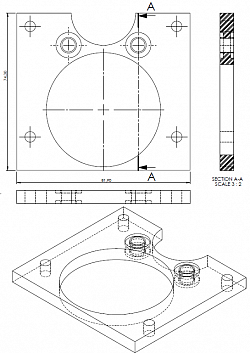

- 10119157 - HP Tantalum Target Assembly

- HP Target Body %99,99 Tantalum

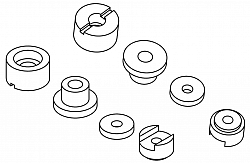

- Target Support Cylinder Set

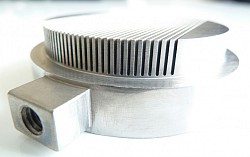

- 10180971 - Copper Hex Grid

- 10180958 - Cathode Single Piece 1910

- 10180956 - Ion Source Cathode Ceramic

- 10180915 - Anode İon Source Rds111

- 10180914 - Collimator .157""

- Target Graphite Collimator

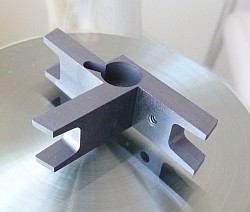

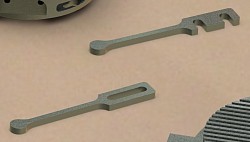

- 10180926 - Clamp Extractor Carousel Rds111

- 10180927 - Clamp Extractor Carousel Dimension 0,660

- 10180921 - Body Extractor Carousel Rds 111, Std Length

- 10180922 - Body Extractor Carousel Rds 111, 0,894 Long

- 10180923 - Body Extractor Carousel Rds 111, 0,972 Long

- 10180924 - Body Extractor Carousel Rds 111, 1,051 Long

- 10180961 - Insulation Collimator

- 10181433 - Ion Source Upper Cathode Rod

- 10180957 - Ion Source Lower Cathode Rod

- 10180909 - Cup Faraday Rds111

- 10180909 - Paper Burn Kit

GE Minitrace Cyclotron;

- 2222918 - 5144105 Anode Service Kit

GE PETtrace 800 Cyclotron;

- 2109838 - 732730 ION Source Maintenance Kit